Wondering regarding the issues that the aerospace industry faces? This article contains not only key challenges but a potential solution to resolve them. Go on reading!

The aerospace industry is a key source of tech advancements and innovation in the contemporary world. World-class engineers empower secure and effective air travel, optimize communication and knowledge distribution, and add much to better consumerism/supply chains within their aircraft projects.

Nowadays, every industry sector faces numerous challenges. However, with the aerospace industry possessing a greater global footprint compared to any other sector, it is undergoing a multifaceted and difficult future.

From various perspectives, the skies look encouraging. Mankind witness high demand for air travel, delays of novel aircraft orders, advanced technology, revitalization in the business aircraft sector, and so on. As far as technology continuously transforms, the following 6 challenges are supposed to play a decisive role in building the future of the aerospace industry.

Looking for reputable contractors that deliver aircraft maintenance services? It is time to start collaborating with Engre, as one of the most popular B2B engineering marketplaces.

Being Cleaner via Reducing Fuel Consumption

Not every human has faith in climate modification. Not every individual trusts in electric propulsion. However, there is good news! The international airlines have undertaken to suspend, and then roll back the increase in their carbon footprint to avert their environmental influence restricting the future extension of air travel. Currently, this encourages aeronautical research to shape the future of aviation.

Lighter structures/components, lower-drag aerodynamics, more effective engines, optimized operations, electrification of platforms, non-traditional configurations, and propulsion are all considered the directions being implemented as the industry intends to support, and if possible increase, its effectiveness optimization tempo to proceed with forecasted air traffic growth.

With the introduction of the first airplanes, their effectiveness has grown an average of 2 percent yearly. To succeed in the long-term targets established for research performed in the US and Europe, this figure of increase in carbon dioxide emissions and specific fuel consumption must grow.

However, the tendency has been modified with changes of generations.

In 2016, the Airbus A320neo possessed 14% less fuel burn compared to the original A320 and gained 21% in 2020 with further optimizations. This is the tiniest improvement that the following suggests.

In 2022, with high solution-design speed, aircraft producers will introduce model-on-model efficiency optimizations of 23% every 25 years. But this is not enough in scale to achieve the stated target (by Europe) of decreasing carbon emissions 77% by 2045 compared to the tech levels of 2000.

The majority of the effectiveness strengthening in Boeing 737 MAX and derives from the novel, higher-bypass turbofans. The engine producers have revealed intentions to bring improvements of 3%. However, more will be required to achieve the goals.

And every new movement is a challenge. For instance, Pratt & Whitney invested about 10 billion US dollars over 15 years to design their geared turbofan and gained an initial 16% fuel-burn decrease on the A320. The manufacturer possesses a road map to a further 22% in savings by 2024.

According to NASA investigations, fuel burn could be minimized by about 49% by 2024, and 63% by 2031, in case a set of innovations apart from simply the engines has been set in motion. This is why engineers considering long term are designing novel aircraft propulsion architectures and configurations.

In accordance with NASA, the contemporary tube-and-wing design might introduce fuel economy up to 46% with enhanced aerodynamics, geared turbofans, and re-designed structures. But to move further, they would demand new approaches. Super effective configurations being researched involve truss-braced wing, the hybrid wing-body, and designs with embedded engines, lifting fuselages, and specific ingestion for less drag.

Specialists believe that the tube-and-wing will enter the 2030s due to drag minimization from active flutter curbing to maintain flexible wings and hybrid laminar stream enabled by aerodynamic innovations. However, to set large-diameter, super-high-bypass engines, snub gull wings will be required.

Currently, electric propulsion is not so huge (with 2-seat trainers) but by 2027 hybrid-electric designs will be able to power aircraft with less than a hundred seats. Increasing larger than this figure will be more challenging, and the clue to further effectiveness and emissions optimizations will be connected with distributed propulsion, where more powerful airframe/engine integration ensures aerodynamic advances apart from that enforceable by other methods.

After all, the aerospace industry will have to get rid of fossil fuels; otherwise, the risk rises for it to be the last user of a vanishing resource. Eco-friendly synthetic kerosenes will prolong the life of liquid fuels for decades, but the aerospace industry will require alternative energy sources anyway in case it wants to go on minimizing its carbon footprint. Chances are that batteries will be modified to satisfy aviation’s demands, or other strategies regarding high-density energy preservation will happen that guarantee a clean future.

Resolving Aircraft Modification

The amount of civil aviation flights is supposed to double by 2050 that will result in a shortage of oil, growth of greenhouse gas emissions, and a negative influence on the surrounding in general. The identification of tech solutions to overcome those global challenges consists in minimizing the consumption of common fuels that includes modifying the design of the aircraft, avionics, engines, and aircraft control platforms.

Powerful growth in the environmental friendliness of the aerospace industry can be gained by minimizing the weight and size of the essential components of the onboard aircraft equipment, i.e. communication, navigation, unmanned supervision platforms, and communication while optimizing their safety and energy efficiency.

Decreasing the maximum take-off aircraft weight with the help of onboard aircraft equipment miniaturization can not only shorten fuel consumption but also reduce the number of flights via raising flight payload.

To bring the tendency to life, a qualitative transformation in the aircraft design is needed, as well as the implementation of truly novel materials for innovative sensors integrated into various components of the aircraft body.

Up to 2025, IoT will greatly influence aerospace logistics and aircraft maintenance. This technology will be applied from 2023 to 2030 to enhance flight performance. Additionally, it will support refining the aircraft’s effectiveness. Some engineering specialists report that the aircraft monitoring platform will be empowered with IoT equipment that delivers top diagnostic performance.

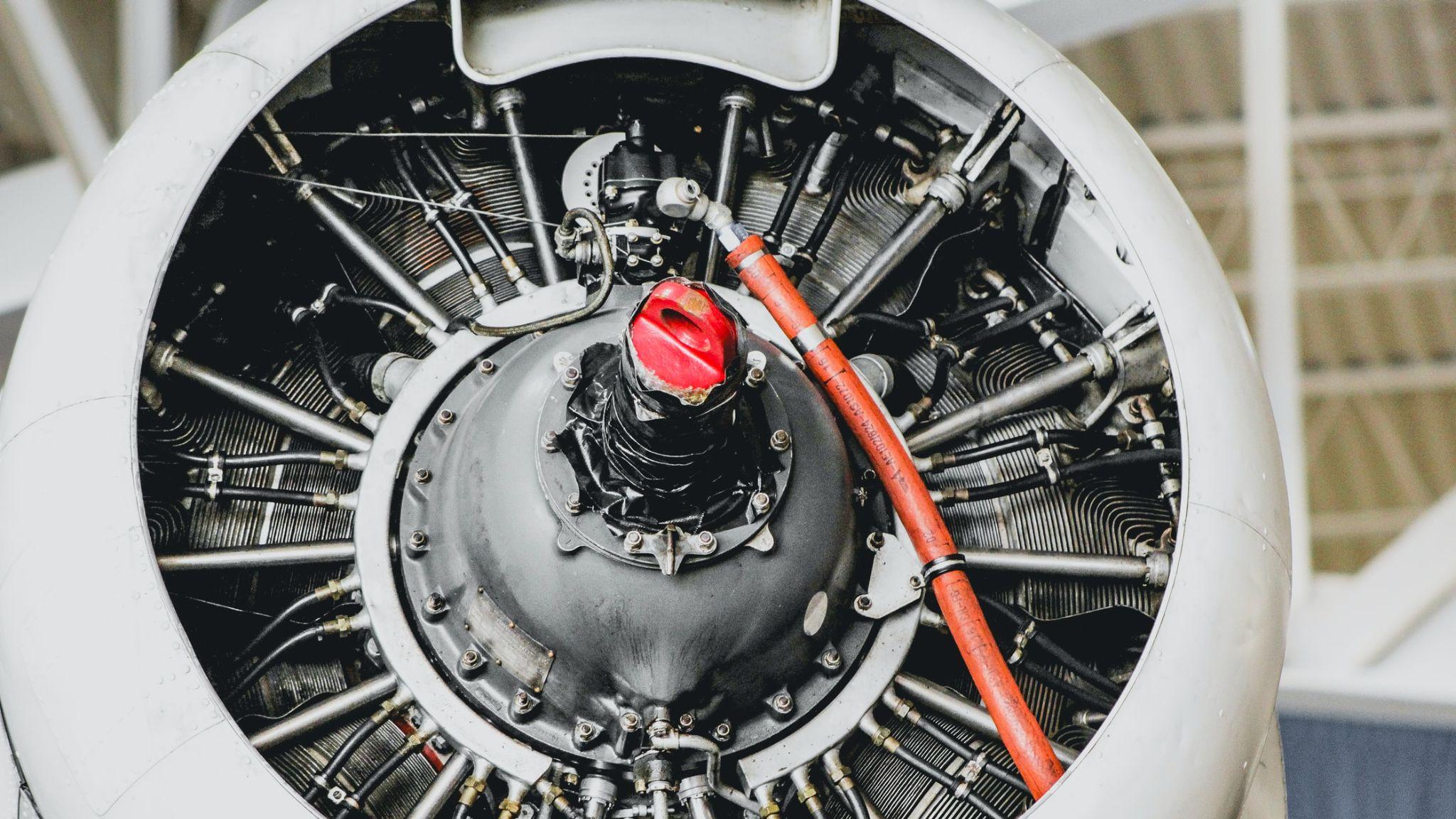

For example, nowadays, contemporary engines possess about 3 hundred sensors. In the future, engines can potentially contain nearly 6 (!) thousand sensors gathering strong amounts of performance info. This practice enables the engines to operate at a greater level.

When it comes to safety, in case airplanes are not connected, they can avert accidents as well as figure out optimal flight routes to economize travel fuel and time. In 2021, the location of the aircraft is predominantly supervised from the ground. Exclusively air traffic managers are aware of where the aircraft is situated (however, satellite-based monitoring is gaining momentum).

Getting Faster with Aerospace Innovations

Internationally, the tempo of commerce and communication has grown with every new revolution in data technology. However, in 2021, air travel is no faster compared to the start of the jet era. Will this problem lead to the comeback of supersonic transport?

In the aerospace industry, many experts (from Boeing leaders to startup owners) are sure that the supersonic transport will return, but they have no idea when. Here, the time has come for innovative Boom Technology and Aerion. The time will come for Boeing, NASA, and Lockheed Martin, when the sonic boom has been taken away as an obstacle to supersonic flight over the ground. For other manufacturers, hypersonic is the solution as supersonic is too low-speed.

The barrier to supersonic air travel is considered economic and environmental factors, such as emissions, noise, boom, price, and fuel burn. In 1999, NASA refused to design their transoceanic SST when the industry claimed that clients would refrain from paying thousands for speed. Investigation re-launched in 2008, however, has accentuated minimizing sonic boom to a degree that will ensure supersonic trip over the ground, currently acknowledged as vital to the economic success of high-speed vehicles.

Withdrawing the prohibition on supersonic flight over the ground demands regulatory strategy, and the controllers need info before acting. They succeeded! In 2019, NASA’s strategy, endorsed by Lockheed Martin and Boeing was realized via launching a low-boom demonstrator to collect info regarding mankind’s reaction to sonic booms minimized from numerous bangs to slight thumps due to re-shaped airframe. In 2020, the research results were delivered to the ICAO to help remove the prohibition on the supersonic overground flight.

The Quiet Supersonic Transport X-plane (equipped with one engine) simulates the shockwave of a bigger 100-seat airliner with a boom amount of 83 PNLdB. Due to improvements in engines and aerodynamics, the novel vehicle would burn less fuel (for 32 percent) compared to Concorde, rendering it more economically appealing. However, fans of speed have no wish to wait long for regulations to modify and low-boom technology to ripen. In 2018, Aerion initiated the design of its 12-passenger business jet in collaboration with Airbus Group, with an official release to start by 2022. Boom Technology has already launched a demonstrator for its 4-seat business airliner. In 2021, the solution can be in economic competition with subsonic business-class flights.

No one from the above-mentioned is low-boom. Both aerospace solutions are based on optimized performance to create their vehicle economically attractive, conducting supersonic travel over water (and subsonic over the ground). Well, this will continue until the rules are transformed.

Both manufacturers were the first to prove the idea that a supersonic travel market does exist. Recently, Aerion has received an order from a reputable operator called Flexjet. Boom has established a partnership with Virgin Galactic. High-speed travel for passengers will happen soon!

Traveling at super high speed 24/7 beyond the supersonic is still an ambitious target, but hypersonic aircraft for both air/space transport will only occur when the military optimizes the technology. Decades of rapid advances performed by the US, Russia, and China will lead to the foundation of the first hypersonic weapons. As soon as scramjet engines arrive at manufacture, investigation regarding rocket/turbine-based propulsion will begin and the hypersonic flight will get closer.

Making Aircraft Quieter

Aircraft is never quiet, that is why it is usually a challenge to find a location for a novel airport. Moreover, widening or adding a runway takes years, and keeping a heliport in a city center is a hard activity. In case they include the potential for unmanned aircraft, supersonic airliners, and flying taxis, the noise gets one of the greatest issues to the future of the aerospace industry.

Because the international major population centers are expected to become megapolises, airports will undergo growing geographic stress even as a requirement for travel continues growing. High-speed rail can potentially supplant aviation for short-range trips if airports don’t improve their capacity without decreasing their influence on the neighborhoods.

To date, the requirement for a more powerful flight performance comes in pair with the demand for less airport noise (greater higher bypass coefficients minimizing sound generation and fuel consumption) however, they could be gaining a disparity. The point is that greater bypass coefficients for bigger performance indicate more subtle nacelles with smaller places for noise reduction when rotors open.

According to numerous investigations by NASA, the common tube-and-wing airliner construction demonstrates great potential to minimize fuel burn. However, that doesn’t refer to noise. Engines can get quieter if fans become bigger, but in case they keep locating under the wing their quietness is restricted. In the nearest decade, the top solution NASA believes to get from a tube-and-wing development is a total of 30 dB.

Withholding aircraft noise adequately within airport territory and far from nearest surroundings demands lowering of at not less than 60 dB. What is the solution? To complement the reduction of airframe noise components, such as slats/ flats and landing gear (potentially with the help of smooth high-lift platforms) engineers should shield engines from the land. This will demand truly innovative aircraft architecture that differs from the current one.

They could transform the tube-and-wing construction to place the engines in the area where the fuselage and wing deliver some protection of jet/fan noise. According to NASA, the mid-fuselage/over-wing nacelle architecture might cut noise by 35 dB. On the contrary, due to its broad fuselage, the hybrid wing-body maintains the best protection of 40 dB. Such protection architecture is vital to creating fuel-saving open rotors valid.

Engineers find it challenging to generate helicopters quieter due to the basic features of rotors, but the advancement is being performed in the operation and design of rotorcraft. The most contemporary lineup of helicopters produces less noise, and best practices/innovations are in design that will minimize sound and noise footprints by 60 percent by 2025. However, more advancement is required in the case of heliports as well as VTOL aircraft are to be retained to play a vital role in transportation.

By the way, helicopters and airliners are not the only sources of noise in 2021. The boom for the implementation of unmanned aircraft platforms, especially for parcel delivery, will create serious acoustic trouble. It is a fact that modern multi-copters and drones are irritating. Nowadays, research is conducted to describe the noise, determine restrictions, and decrease the influence but it is still in its formation phase. The success of this research will play a decisive role not only for unmanned vehicles but also for ambitions to utilize novel kinds of aircraft to enrich the industry.

Getting Closer to Ordinary People

Around the globe, the majority of cities have grown outside the opportunity of their land transportation infrastructure, and designing new railways/highways in built-up locations is harmful and costly. International aerospace experts consider this as a unique chance to introduce a third dimension to the travel of ordinary people.

The above-mentioned are called individual air vehicles, flying cars, and air taxis. All of them guarantee on-demand mobility. But the key goal consists in utilizing aircraft to get rid of the land transport restrictions in the form of roads overloaded with shuttle trains.

Experts witness the fusion of technologies being designed for unmanned aircraft, initially electric propulsion and autonomous platforms, with the crucial requirement for an alternative to generating more rail/road ties. At the same time, they admit the obstacles to implementation are numerous. They involve security, operating cost, certification, noise, simplicity of utilizing, emissions, and airspace integration.

They will resolve those obstacles via unmanned aircraft, involving the certification of little unmanned transport, their secure adoption into low-level airspace, and tolerance of aircraft noise within the society. Experience during 2010 – 2020, especially with introducing standard urban delivery solutions via drones already plays a great role in establishing client-friendly on-demand aviation.

Becoming Cheaper

The manufacturer called Aerospace has won a reputation for problematic solutions in terms of budget. Their step-change aircraft, like Lockheed Martin’s F-35 and Boeing’s 787 has appeared to be far more expensive and complicated to design than forecasted. As far as commercial producers aim at higher performance and military manufacturers for moves towards capability, price is a serious case for both sectors.

It didn’t play a big role in 2000 and 2010 when solutions with technically impossible targets were regularly released and revoked. But in 2021, taxpayers, clients, and shareholders require affordability. Consequently, program performance will be a serious issue.

The creation of more innovative as well as integrated development tools is supporting, involving the design of model-oriented platforms that more relevantly predicts the manipulations that can lead to challenges during the design phase. Wider implementation of computational evaluations and early-stage optimization enable more variants to be explored while looking for a top solution to the requirements. More automation in design and manufacturing maintains less cost and time.

In the meantime, innovative technology starting from materials to production is empowering design modifications that can result in creating the engineers’ activity more difficult. Additive production ensures the 3D printing of multi-purpose components that long ago were beyond to develop.

To resist that tendency, they require the hard-learned lessons from challenges with the latest projects with requirements to be established and introduced. Innovative technologies have to buy their path to the platform. The tendency is brightly demonstrated in the B-21 bomber designed by the U.S. Air Force and the optimized 737 MAX and A320neo models.

The next-gen commercial airliners and combat aircraft will show whether the troubles connected with F-35 and the 787 have been absorbed. NASA is already pronouncing the requirement for a unique next-generation system to guarantee air prevalence after 2027. In 2021, the top manufacturers called Boeing and Airbus have already acknowledged that every novel generation of airliner can’t have a higher price compared to the previous one.

And one more brand new single-aisle aircraft or fighter may not be released before 2025. By this point, a wide range of innovative technology will have been invented and be searching for the application.